Sometimes the simplest ideas are just the best. With 3D printers, you are almost always limited in terms of object dimensions. Only what fits inside the printer can be 3D printed. Printing large objects requires even larger 3D printers. The Z-Unlimited by inventor Joris van Tubergen circumvents the limitation in height with creative thinking and relatively little effort.

is a designer, inventor and 3D printing expert. He is a speaker on 3D printing and teaches digital fabrication at several educational institutions. Joris himself studied Industrial Design Engineering at Delft University of Technology in the Netherlands. Since the start of the Fablab, he has supported the development of the RepRap – an open source 3D printer that you can build yourself. In 2010, the popular RepRap masterclasses resulted in the development of the Ultimaker: At the moment a world leading desktop 3D printer firm. The 20 x 20 x 20 centimetres build volume of the Ultimaker is relatively good already for 3D printers in its price range.

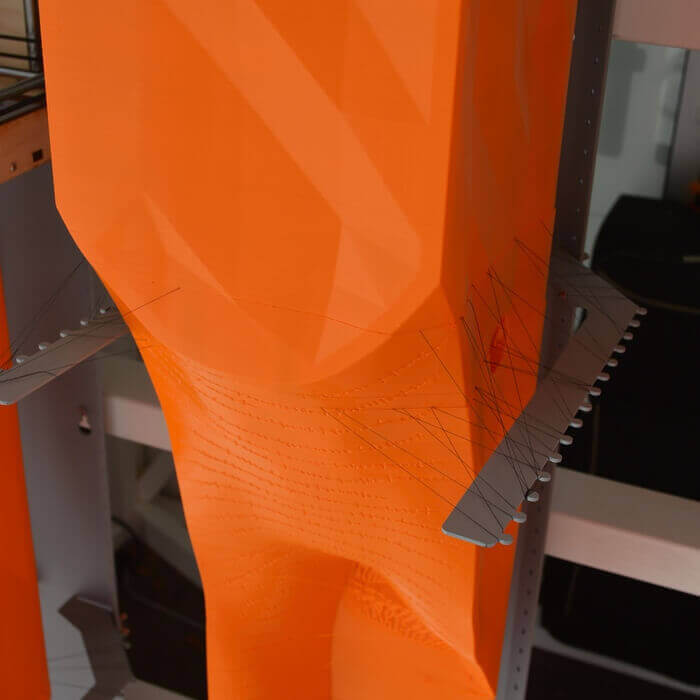

For the Ultimaker (and its successor to the product line, the Ultimaker 2), Joris came up with a solution to bypass the height restriction he named Z-Unlimited. To put it very simple, the printer chassis is turned upside down, and the z-axis gets extended. The material extruder is then turned again so it faces the ground again and prints downwards as it usually would.

The conversion takes only 10 minutes

On its prolonged z-axis, the printer then can move from the bottom to the top. Whereas the build plate in an unmodified printer moves down with every finished layer of the 3D print, it stays steady in position and the 3d printer chassis moves up instead. Both ways, you increase the distance between nozzle and 3d printed object after every finished layer to make space for the next layer. The whole conversion takes only 10 minutes and enables so many prints that had to be made in parts before. For anyone who regularly prints larger objects, especially when they only exceed the build volume on one axis, this is a perfect solution.

This technique is so simple, you wonder why nobody thought of it already. While prolonging the x- and the y-axis would compromise the sturdiness and accuracy of the printer, the z-axis seems to be no problem at all. Tubergen used the extension on prior projects without any trouble. The functional principle could be transferred to almost any 3-axis 3d printer, and as Tubergen is involved in the open source community, we´ll rather not see him patent his invention and market it extensively. He doesn´t even want to continue the production of the Z-Unlimited with an own company after the Kickstarter campaign.

On a side note, van Tubergen also developed a genius but simple gimmick to achieve support structures for prints that get higher than usual. It uses a mesh of yarn that gets pulled out when it isn´t needed anymore. We surely will hear more from Tubergen, as he is actively involved in many 3d printing projects, for example, this 3D printed Canal House in Amsterdam.

https://www.youtube.com/watch?v=7-93G_YxKGA

You can buy an Ultimaker directly at iGo3D.

License: The text of "Pimp your Ultimaker to print in unlimited heights" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.