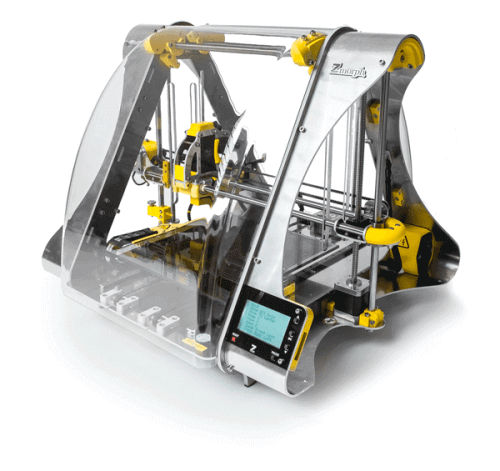

If you find that you’re deterred from using a 3D printer because your designs require subtractive techniques, Zmorph might have the ideal solution.

According to their website:

“Sometimes 3D printing is not enough. Additive manufacturing disrupted the scene, but in a vast number of cases, subtractive methods are still the way to go. Like all technologies, 3D printing has its limitations, stemming from the very foundation of how 3D printing works.”

In those instances where a project is not best realised by 3D printing alone, the obvious choice is to reach for a different technology — such as CNC milling or laser cutting — which is where the Zmorph excels.

Zmorph and the Custom Mechanical Clock

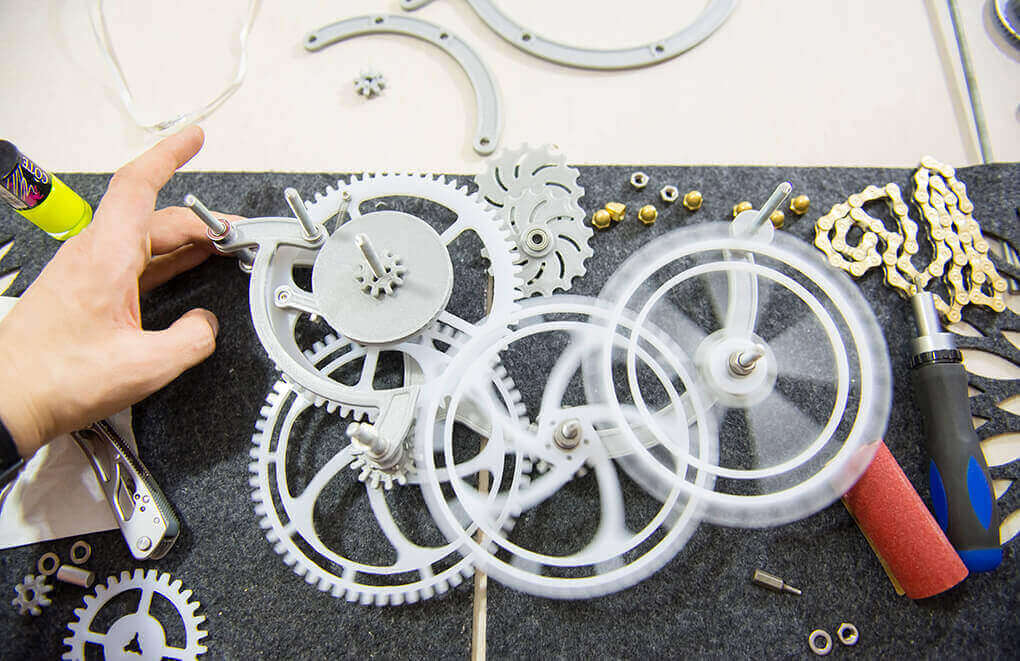

To assemble the clock, Olczyk used around eighty different parts (with a few exceptions such as chains and screws). All of these parts were made using the Zmorph 2.0 S Hybrid 3D Printer and Voxelizer Software — simply by changing the toolhead.

Most of the parts consist of various types of gears, some of them were best 3D printed, some of them CNC milled. And this isn’t the only interesting feature about the Zmorph, as they also claim they can print in multicolor with multiple materials printing.

As a proof of concept, the mechanical clock is certainly impressive. “(The Zmorph 2.0) will serve you as a versatile object-maker, for 3D printing, CNCmilling, laser-cutting, and 3D object scanning,” boasts the website. “Perfect for product development, prototyping, and small batch production. Bring your ideas to life and enter the world of endless creation.”

If you’re interested in learning more about the making of the clock, check out the video:

License: The text of "Zmorph Shows How to Create a Custom Mechanical Clock" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.