Zortrax releases three new materials for the Inventure 3D printer – durable Z-ULTRAT Plus, Z-SEMIFLEX, and Z-SUPPORT Plus.

Earlier this year, the Polish 3D printer manufacturer Zortrax released the highly anticipated Inventure, a compact 3D printer with industrial-grade ambition. Since joining the Zortrax family–which includes the M200 and M300–the Inventure has sparked a fresh jolt of innovation throughout the industry.

Not only is it the smartest 3D printer to come out of Olsztyn, Poland, it has also led to the development of other unique Zortrax products and materials. Equipped with a closed, heated chamber and HEPA filter, the new Inventure 3D printer provides a consistent and safe work environment for all users. With two extruders, the Inventure is able to print base and support material together. The printer also comes with a DSS station, allowing for quick and easy dissolution of support material without manual labor.

Now, in order to expand the production capabilities of the Inventure, Zortrax is rolling out three new materials – the extremely durable Z-ULTRAT Plus, Z-SEMIFLEX, and new Z-SUPPORT Plus.

These new materials will significantly broaden the possibilities of what can be accomplished with the Inventure 3D printer. Until now, users could only choose between Z-PETG and Z-PLA materials. Z-PETG is characterized for having high resistance to chemicals and oils, while Z-PLA provides high precision of the details, very few geometrical limits to the shape of 3D printed objects, and biodegradability.

While these two filaments are certainly useful for a variety of applications, the latest expansion to Zortrax’s material range will open up the Inventure to new horizons.

Zortrax Releases New Materials to Increase the Capacity of the Inventure 3D Printer

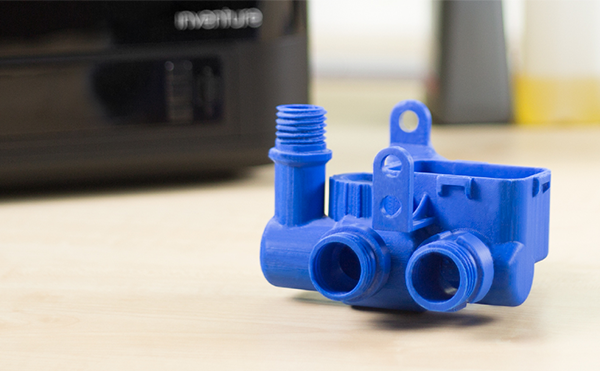

To start, the Z-ULTRAT Plus was designed to print production-ready models or parts with complicated mechanisms. It is also suitable for creating exceptionally durable prototypes, as well as models that are printed in one part without need to connect with other parts. This material is based on an ABS compound (Acrylonitrile – Butadiene – Styrene), which is commonly used in both 3D printing and traditional manufacturing, used to create anything from toys to automotive components.

The Z-ULTRAT Plus works in tandem with the new Z-SUPPORT Plus, a support material that is completely soluble in water, eliminating the need for manual post-processing. Additionally, this solution allows users to design 3D models with extremely complex shapes. Z-ULTRAT Plus is also offers resistance to temperatures over 90 °C, a low shrinkage ratio, and a high index of connecting the layers in the 3D printed model.

Lastly, the Z-SEMIFLEX is a TPU 98A-based material with resistance to high temperature and elasticity. This makes Z-SEMIFLEX resistant to tearing, abrasion, impact, and temperatures over 130 °C. Models printed with Z-SEMIFLEX will not be prone to shrinkage, and are also impervious to chemicals and oils. The material also works with Z-SUPPORT, meaning that 3D printed models are ready-to-use after some time basking in the DSS station. This particular material is ideal for prototypes and models that will be subjected to intensive testing.

While the development process for the Inventure took several years to complete, Zortrax’s latest machine is finally ready to take on the high-end desktop 3D printer market. With a number of new professional materials added to the company’s portfolio, users will now be able to break the boundaries of 3D printing, bringing their experience to a new level.

To learn more about the Inventure 3D printer and the new line of materials, visit the Zortrax website.

This article was sponsored and paid for by Zortrax.

License: The text of "New Zortrax Materials Expand Production Possibilities of Inventure 3D Printer" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.